Chippewa Falls, Wisconsin – March, 25 2020.

A HISTORY THAT BEGAN IN 1922.

Joseph Bischel founded Northern Crossarm Co. in 1922 to manufacture wood crossarms for the telephone companies.

When the family business transferred to the next generation in the 1970s, the telecommunications industry was changing, and more phone lines were being installed underground. Northern Crossarm recognized the need to expand the business and purchased equipment to pressure-treat wood. This expansion paid off, and the business grew.

After the Chippewa Falls, Wisconsin, company transferred to the third generation of Bischels, crossarm production ceased and the company focused entirely on pressure-treated wood.

Today, with Joseph’s grandson Patrick Bischel running the company, Northern Crossarm continues to grow. Employing 30 people, the business currently operates three kilns with a drying capacity of 15 million board feet annually. The company also installed a new molder last year to develop additional decking projects, along with new coating equipment to double-brown kiln-dried wood production capabilities.

“Just like my grandfather did, we look for ways to offer value-added, innovative products,” Bischel said. “Pressure treated wood has become a commodity, and it’s very price-sensitive. To set Northern Crossarm apart, we focus on offering higher quality products and unique products.”

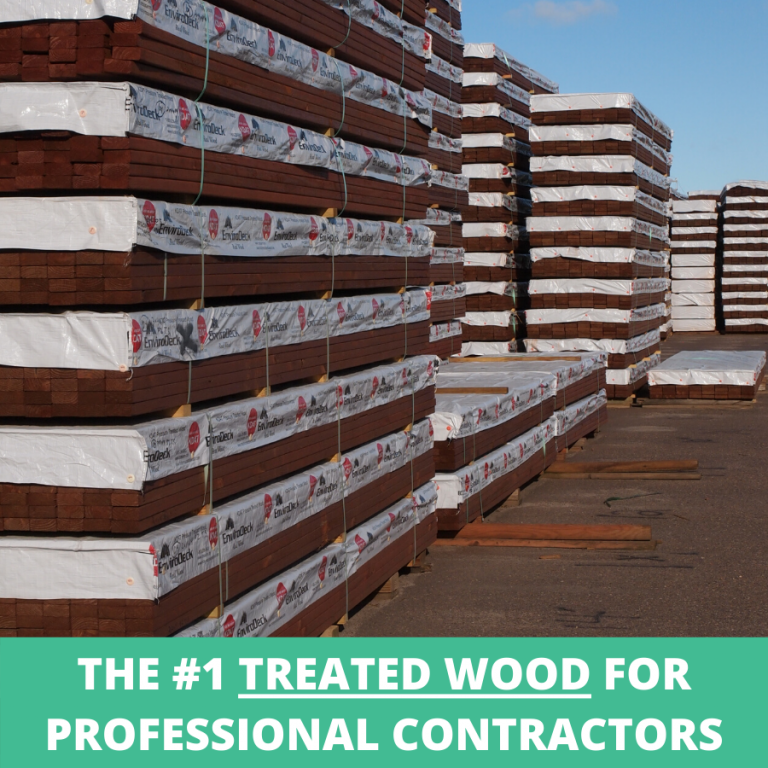

KDAT BROWN – A TREATED LUMBER INNOVATION

Offering brown kiln-dried pressure-treated wood is one such change that is paying off. The rich, brown finish looks good, performs well and holds up over time. Because kiln-dried lumber is relatively lightweight, it’s easy to transport and handle. It can also be painted or stained immediately upon installation.

As a result of Northern Crossarm’s commitment to staying ahead of trends and customer needs, and maintaining high standards, the company has gained a reputation for the quality of its products.

“A treating plant can produce the amount of wood we do in a year with six people,” Bischel said. “We have 30. Those extra 24 people help us maintain the highest quality product available. People spending as much as $1,000,000 on their decks don’t want a product that’s shoddy. They want products that meet their high standards for an outdoor living project they will use and love for many years.”

The majority of Northern Crossarm’s wood is used for decking and fencing. Outdoor projects have evolved significantly over the years. The square footage cost of a deck is no longer significantly different from the costs for a home’s indoor spaces. Using high-quality products that hold up is increasingly important for builders and homeowners.

Northern Crossarm continues to grow. It currently has distribution throughout the Upper Midwest and Rocky Mountain regions and is exploring additional markets, including Chicago and Ohio. Additional growth is expected as a result of a new production line coming in June as well.

To learn more about KDAT wood, please contact Northern Crossarm at 715-723-4100 or visit online at crossarm.com

*Article published in Building Products Connection, April/May 2020.